Making hydrogen economical, according to Albert Tarancon of the Catalonia Institute for Energy Research, would be “the tipping point for a widespread deployment of the hydrogen economy,” supported by the “great” potential of 3D printing useful materials inside the hydrogen energy industry.

In a deeper look into this burgeoning energy sector, Tarancon offered his insights with 3dprintingindustry.com on how 3D printing may help transform the concept of a hydrogen economy from concept to reality.

According to the International Renewable Energy Agency (IRENA), hydrogen is expected to account for 12% of global energy consumption by 2050. Green hydrogen, according to the agency, has the potential to dramatically disrupt global commerce and bilateral energy ties, as well as contribute to the formation of new centers of geopolitical influence in the future.

Hydrogen is a clean fuel that produces only water when burned in a fuel cell. Hydrogen may be generated from a wide range of domestic resources, including natural gas, nuclear power, biomass, and renewable energy, making it an appealing fuel alternative for electricity generation. However, hydrogen fuel is now most often generated using natural gas reforming and electrolysis procedures.

While hydrogen fuel derived from renewable sources has enormous potential for future clean energy generation in terms of environmental credentials, it is costly and, due to its high flammability, is not the safest form of energy available. It’s also worth mentioning that not all methods of manufacturing hydrogen are “clean” — hydrogen created from renewable sources is known as “green hydrogen,” and it’s still in its early stages.

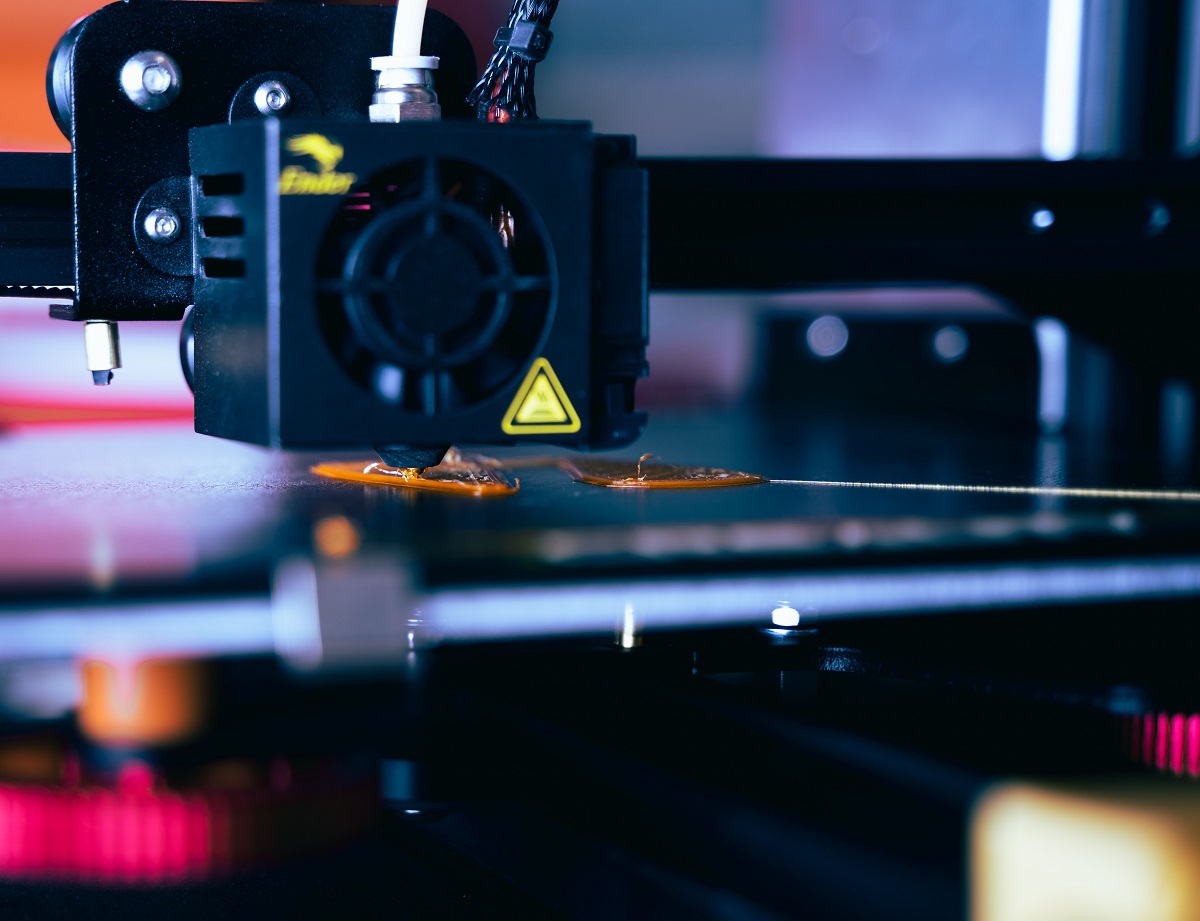

Lux Research listed 3D printing and green hydrogen as two of the top 12 promising technologies to watch in 2020. Based on data from patents, scholarly articles, and financing, as well as expert input from Lux’s analyst team, the yearly study identifies the top technical advancements that will have the most effect over the next decade.

Previously, the two technologies were combined to create a unique hydrogen production catalyst that was said to be 20 times more efficient than others on the market. The catalyst, developed by the Korea Advanced Institute of Science and Technology (KAIST) and Korea Institute of Science and Technology (KIST), might serve as the foundation for a more cost-effective technique of creating hydrogen in the future.

Leaders in additive manufacturing have also recognized 3D printing’s future prospects to position itself as a forerunner in the increasing race to identify sustainable technologies capable of creating clean hydrogen on a big enough scale to fulfill the industry’s present and future demands.