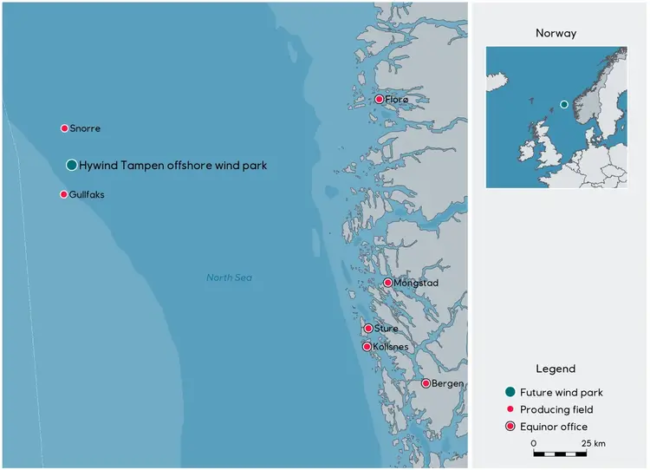

The Hywind Tampen floating offshore wind farm off the west coast of Norway began producing its first power on Sunday. According to Norwegian energy firm Equinor, it will supply power to oil and gas fields. At the same time, it will significantly reduce emissions.

According to the company, the power was delivered to the Gullfaks A, the platform in the North Sea.

Wind is coming

Once fully operational, Hywind Tampen is expected to meet approximately 35% of the electricity demand of the Gullfaks and Snorre oil and gas fields. In periods of higher wind speed, this percentage will be much higher.

This will limit carbon emissions from the fields. Equinor estimates the CO2 reduction will be overall at least 200,000 tonnes per year.

Hywind Tampen, when completed, suppose to have 11 turbines with a total capacity of 88 megawatts (MW).

However, only seven turbines are planned to be connected at first. The final units are delayed until next year due to global supply chain bottlenecks, Equinor says on its website.

Largest floating wind farm

Even with only seven turbines operational, Equinor claims Hywind Tampen will be the world’s largest floating wind farm, with a capacity of 60 MW.

Equinor already operates a 30 MW offshore floating wind farm in Britain. Hywind Scotland is under Equinor since 2017.

According to Equinor’s website, Hywind Tampen is the world’s first floating wind farm to power offshore oil and gas platforms. It is considered an essential step in industrializing solutions and reducing costs for future offshore wind power projects.

It’s a test for bigger wind farm

Also, Hywind Tampen supposes to be a test bed for further development of floating wind – it will explore the use of new and larger turbines, installation methods, simplified moorings, concrete substructures, and integration between gas and wind power generation systems.

The floating wind farm will feature 11 wind turbines that have been upgraded from 8 to 8.6 MW. The capacity in the export system and on the platforms has not been upgraded in accordance. But the increased capacity may contribute to an increase in yearly total production due to increased uptime. Operational experience with completed facilities can also help to improve production capacity by increasing the utilization rate.